Business Owners

Production Managers and Directors

Transfluid

Super Charge your production.

With award winning solutions to complex tube processing challenges.

Here is a selection of Completed High Performance Solutions readily transferable to a variety of industries.

Whether you are thinking of a single stand alone machine for your next project,

a fully automated production cell

or some where in between

This leading-edge philosophy goes beyond the high demands of the: aerospace, automotive,

furniture, display, medical aides, Hydraulics, HVAC, Busbars, Oil & Gas, Ship Builders, Power

Stations, Architectural and General Tube & Pipe Bending industries.

Whether you’re completely new to fully automated systems or one of our tenth-time returning

customers our team of specialist engineers will make you very welcome when you visit

Transfluid’s prestigious Schmallenberg, Germany showroom for a live or remote demonstration

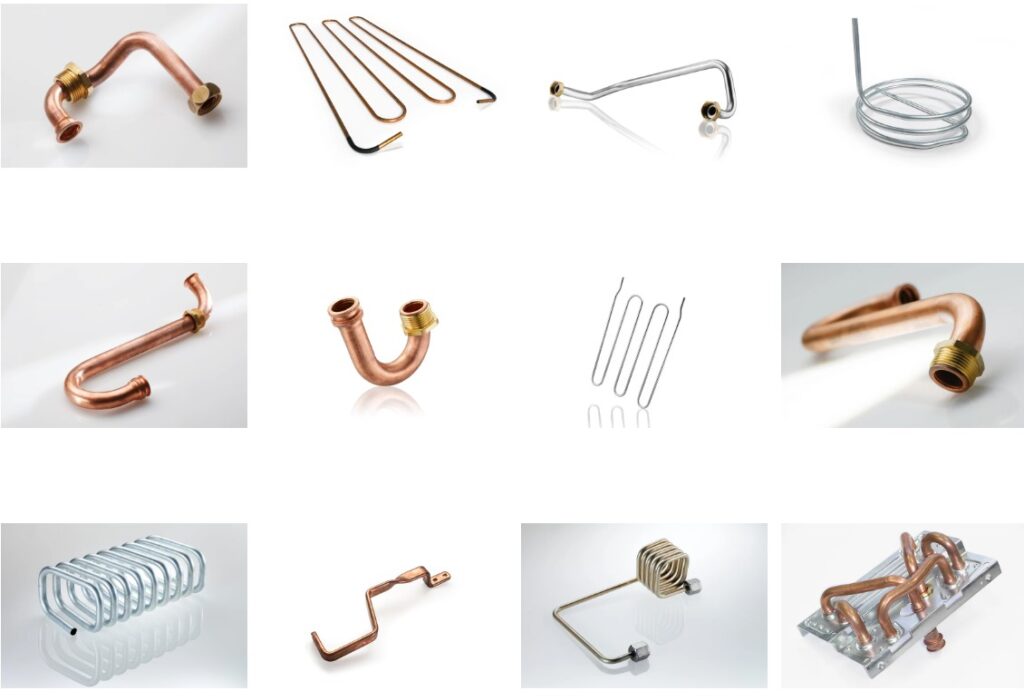

A small selection of tubular and Busbar parts manufactured using bespoke

Transfluid Hands FREE fully automated production cells.

Ticking all the right boxes.

Providing our automotive and hydraulics customers with an

Unfair, Hassel Free, Cost Cutting Advantage.

Wide range of handling systems

Minimising manual input maximising work flow output

Loading systems, whether it’s bunker fed straight tube or from coil

take finished parts away with little or no other manual input

Rewards, Benefits and Cost Cutting Advantages:

Affordable investment.

Cost Cutting, Maximising return on investment ratio

Extremely compact, space saving small footprint

High flexibility for short or large batch runs

Bending with or without mandrel

Tube ends machined / formed on both A and B ends.

Expandable to meet your changing needs

Hole punching within the bend programme

Lubricants that eliminate the need to wash the tube after bending

Low lubricant consumption

User friendly central CNC plant control

Fast, easily accessible tool change

Modular plant design

To name just a small selection of possibilities.

Let us make your journey ‘Effortless and Fuss FREE!‘

So, Whether you are thinking of a single machine for your next project,

a fully automated production cell

or some where in between

Come direct and meet Transfluid’s expert engineering teams 🙃

A live or remote demonstration can be arranged and is recommended

Trust our automation experts to tailor the perfect package for your next project.

Experience Transfluid’s world class manufacturing and prototyping facilities

designed and built to support our customers so you hit the ground running

.For details, we invite you to reach out to me

I’ll be your personal contact throughout your

onboarding enquiry with us.

Please direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news on to team

members / colleagues who you think may benefit.

Thank you in anticipation for your support