Maximum bending freedom.

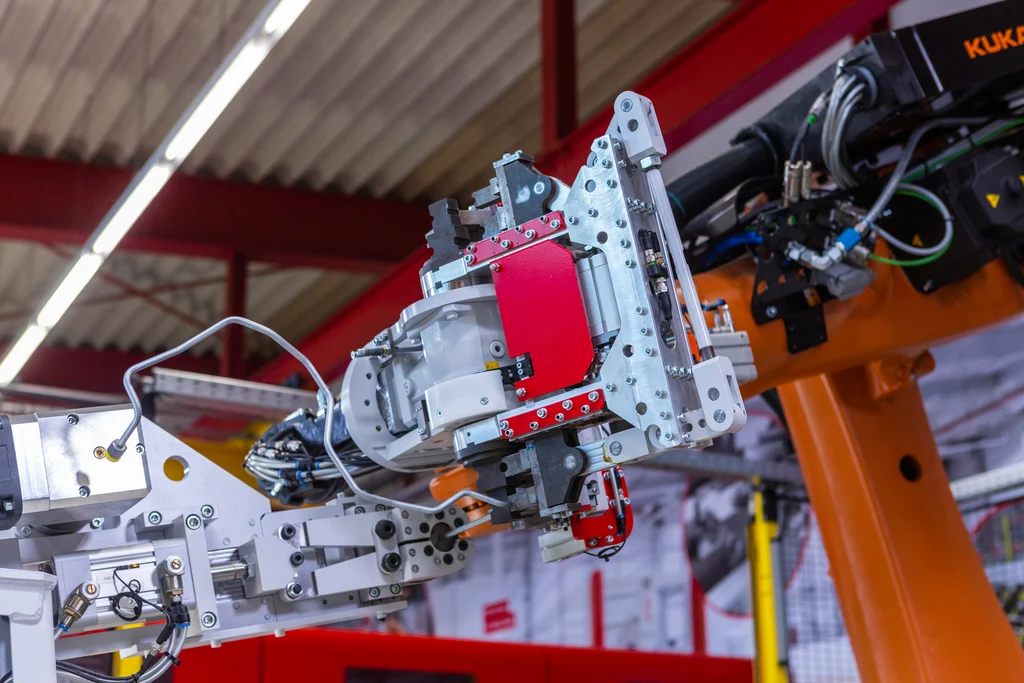

The robotic bending technology from: 6mm/od up to: 22mm/od combines the greatest

versatility in manufacturing steps and simple handling. The robotic head is capable of right

hand and left hand bending in the same bending programme.

The eight synchronised and fully electric axes give maximum versatility when processing

tubes. The bending process on tubes, including the processing at the ends and add-on

component can be done without any problems. The add-on components can be positioned

automatically, if needed. A radii/plane changer with up to 6 tools per bending system is

integrated to give maximum flexibility.

High Definition Expanded processing, bigger output

The bending cells can be equipped with one or two integrated robotic bending units. With the

innovation and development by transfluid, a production cell with two robotic bending machines

can not only bend a tube in both directions, but each robot is also capable of

processing a different geometry.

A production with one or two robots and without a set-up process makes it possible to

bend long pipes with almost no oscillations.

T BEND Robotic bending technology

Bending processes on tubes, as well as end processing and

adding of components is an option

Intuitive operation

Eight synchronized, fully electric axes

Handling included

Bending at every position

The robot as a machine

A complementary concept of Transfluid’s advanced ‘t motion’ automation systems is the option

to use the robot not only for handling, but as a machine. “In a recent project, we had to find a

solution and decide whether to install a bending machine and automate it via a robot, or simply

use the option of using a robot as a machine,” says Stefanie Flaeper M.D. Transfluid.

To make that happen, Transfluid engineers simply put a bending machine in the robot’s hand.

This robotic bending machine is capable of right-left bending in a single clamping operation.

And it is extremely flexible in doing so, especially when long tubes are to be bent – or, for

example, tube-hose combinations where the hose has already been assembled before

the bending process.

Automated without tool changes and vibration-free

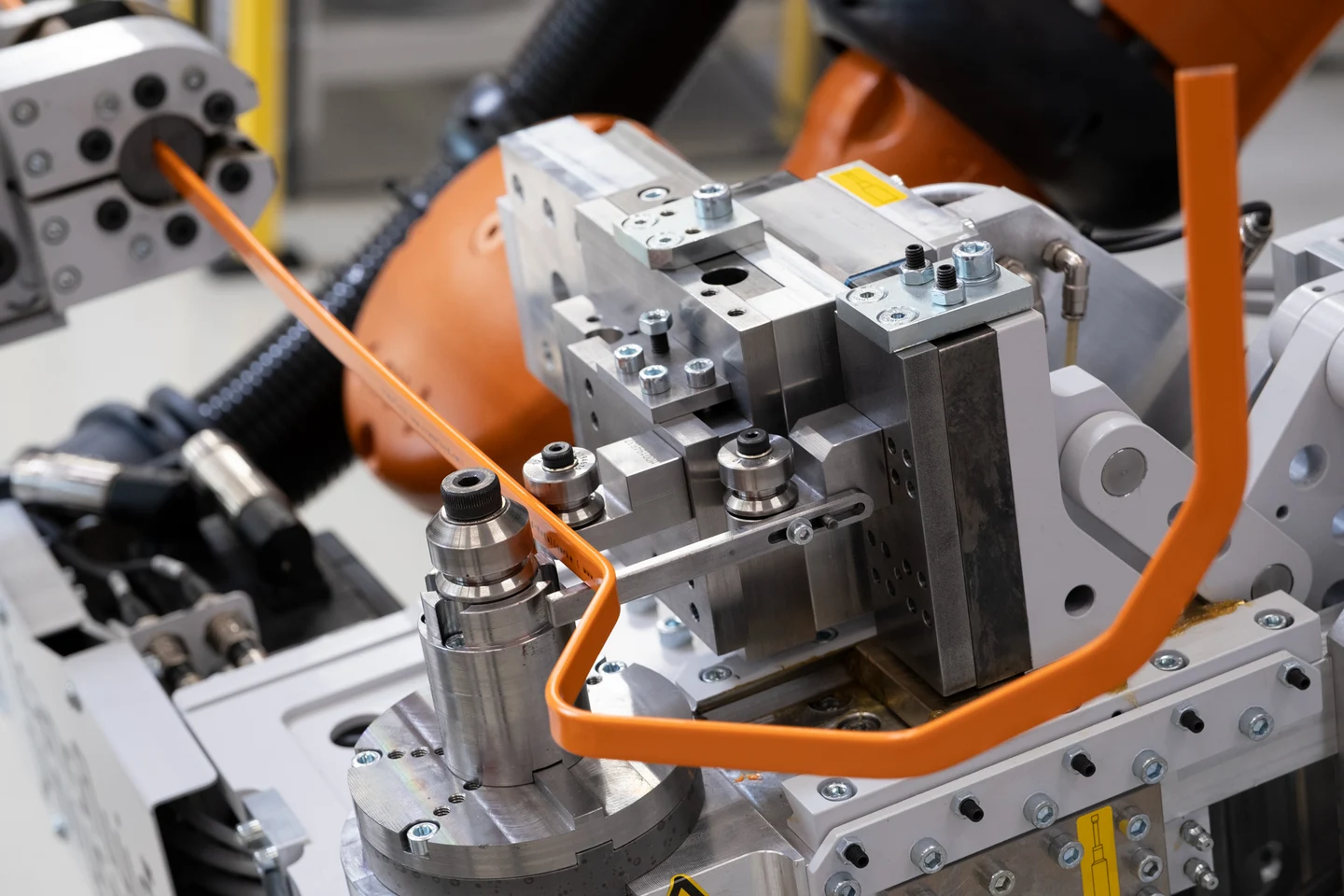

Because the bending heads can also be provided with several levels in this way, it is

possible to process different tube diameters without changing tools.

The advantage of such a robotic bending system is obvious: Long tubes can be bent automatically without major vibrations, and the bending speed is kept relatively constant

over the entire length. The handling of the tubes from a magazine and the transfer to

a deposit after processing is provided by the robot.

This means that steel tubes up to 22 mm in diameter can be bent without mandrels.

Robots also bend tubes that have already been processed

In addition to conventional bending methods, another process is already available for bending

tubes with internal mandrels by robot. This is exciting if the workpieces have previously

been machined on both sides, for example.

The robot can then start bending from both sides. In this way, the Transfluid concept opens up

the impressive possibility of bending on both sides to the final shape without additional length.

transfluid® Busbars & Solid-material

With transfluid®, you bring high end technology to your production. Our solutions, services

and systems are attuned to what you need to produce on the world market level.

Extremely long busbars cut and bent automatically.

Bending busbars for electric cars is a crucial step that affects the efficiency and performance of

these vehicles. Precision, choice of materials and innovative technologies are crucial to ensure

that the power distribution systems in electric cars operate reliably and efficiently. While the

automotive industry continues to grow and develop, the technology used to produce busbars

for electric cars also continues to advance to meet the increasing demands.

The bending and forming specialists transfluid have now presented a key development step at

FABTECH 2023. Transfluid have developed a bending robot specially to meet the

requirements for the production of busbars, capable of processing busbars with a cross-

section of up to 60 mm² and a stretched length of up to 3,000 mm.

It will be my pleasure to assist you with your

tube, wire, and profile bending challenges

A live or remote demonstration can be arranged

and is recommended

Direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-newsletter on to team

members / colleagues who you think may benefit.

Thank you in anticipation for your help.