Expanding Boundaries

Working together we can find the

right solution to take your ideas

to the next level!

Find a standalone machine for your next project

or a fully automated production cell

See video demonstrations below

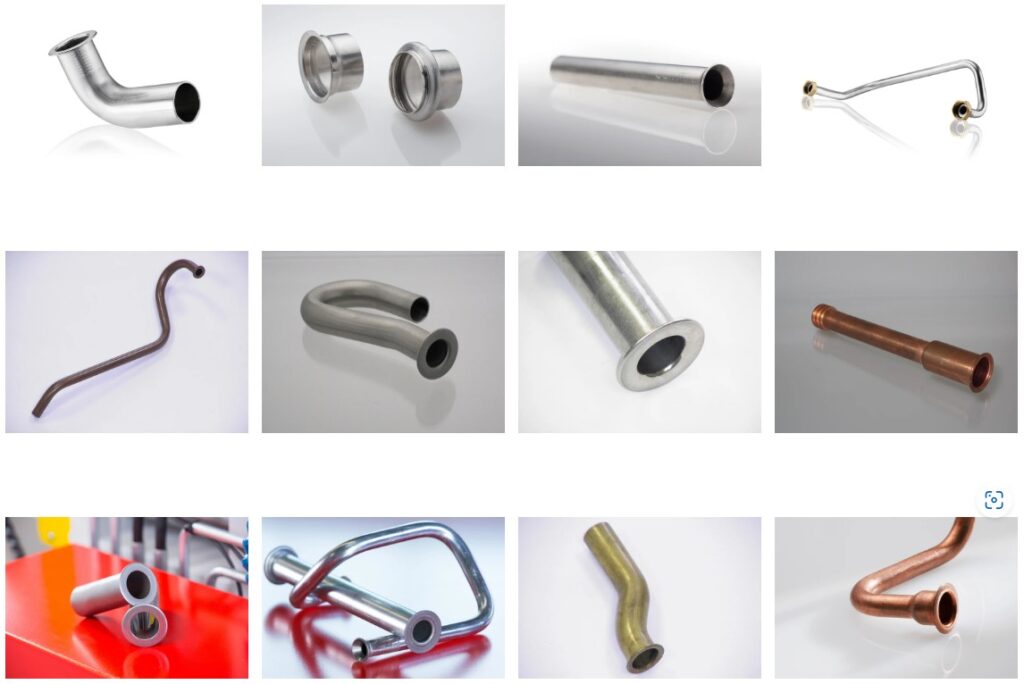

Where we cover all

tube end forming styles and variations

Ignite your imagination and

go to the next level

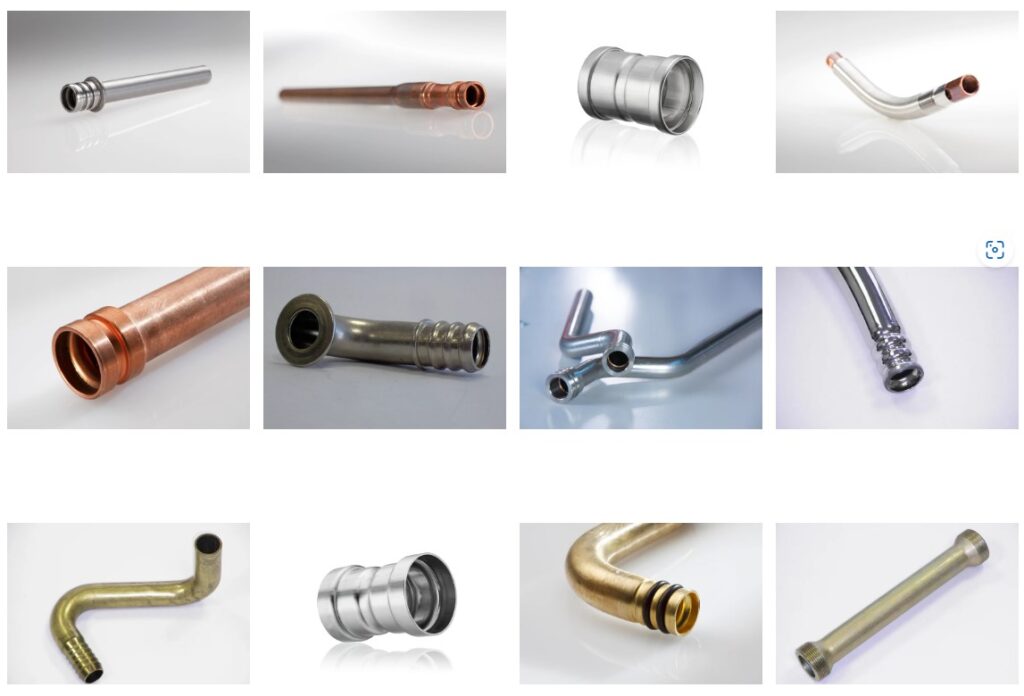

UMR ROLLFORMING MACHINES

The UMR tube forming machine and its special

tumble method and contoured flaring mandrels guarantee

high quality as standard. It produces perfect and mirror-

like sealing surfaces when forming tubes up to a

diameter of 325 mm.

SRM ROLLFORMING MACHINES

Many forming options with one type of machine: forming,

cutting, before or after bending and threading.

Our SRM forming machines are ideally suited for the

production of challenging contours for sealing elements

and for the generation of extremely good surfaces.

REB AXIAL FORMING MACHINES

Accurate forming with fast tool change.

Our REB axial forming machines, with their

compression power of up to 1,300 kN are

particularly well-suited to effortlessly mastering

complex geometries.

With up to 6 forming stations in

combination with an additional clamping unit they

will satisfy your most demanding requirements.

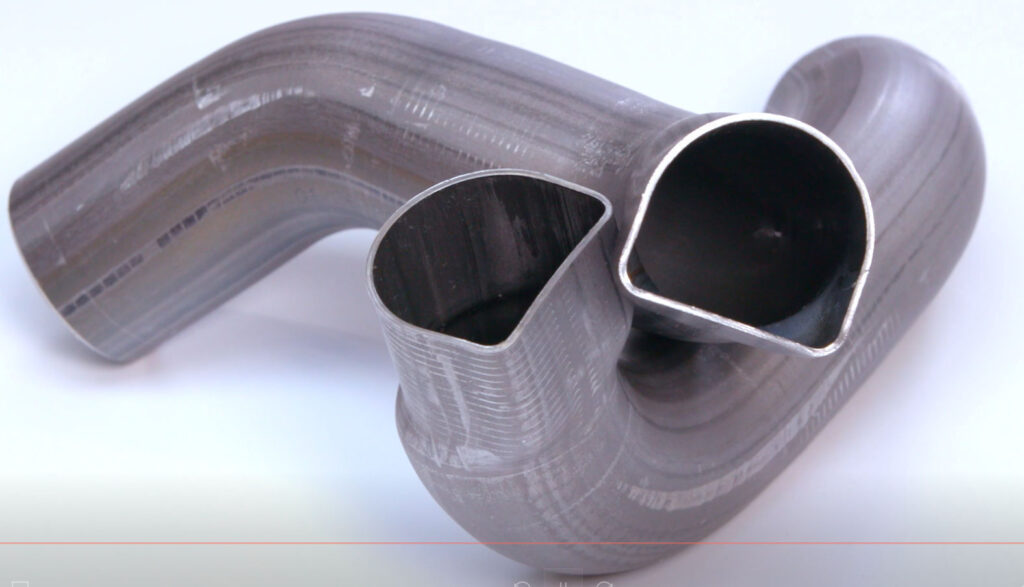

COMBINATION MACHINES

Highly demanding forming geometries in one

work sequence: in our combination machines

we have combined the benefits of axial and

roll-forming in one single system.

Further processing step can be

integrated without any problems.

Transfluid EX3076

Exhaust End Forming

Single station – Two station or Three station

Exhaust three station end forming machine

Expand – Reduce – Slot

tube sizes from:

30mm/od up to 76mm/od

Ignite your imagination and

go to the next level

Intelligently Recombined: Axial and Rolling

Find the right solution for you

With the new generation of combination machines, we have continued to develop the new

diversity for forming pipes. Complex geometries can be formed directly on the tube end

effectively eliminating the need of high-cost and expensive turned parts being soldered or welded to finish the part.

Improved process freedom

See what you can do…

Implementation of the combination can be specified by you or based directly on the forming

geometry. This is usually done using up to 6 axial forming stages and at least one rolling unit.

Trimming, as well as axial and rolling forming, may require two rolling stations.

Compact and universal

Simple trimming or deburring after forming at the pipe end are simple and easily achieved

using our compact units. Therefore, all the axial forming machines and combination machines

bytransfluid® are equipped with one or several single-drive axes. They have a servo-electric drive

and can be used in each of the holders for the forming stages, making the system very flexible

and compact. Apart from this, the equipment of our combination machine with electric drives

permits diverse processes and very precise positioning of all forming tools.

Whether you’re completely new to tube bending and endforming or a tenth time

returning customer. You can take advantage of our team of specialist tube processing

engineers to assist you with your next project and maximise your return on investment.🙃

It all starts here:

A live or remote demonstration can be

arranged and is recommended

Please direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news on to team

members / colleagues who you think may benefit.

Thank you in anticipation for your support.