Transfluid® DB20101K

Mandrel tube bending workstation

Compact and very efficient

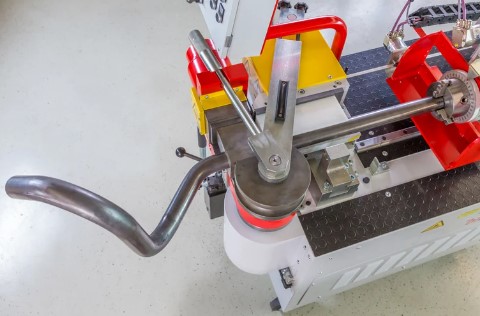

The DB20101K is extremely robust and easy to operate mandrel tube workstation.

A selection of setups is available to process tubes of different lengths, with an operational length up to 240“

Our compact and mobile bending machines can now be controlled easily with a touch panel.

This opens up new possibilities, like displaying the comparison of target and actual values for all axes.

Control of the tolerance of the length and the rotation means very little involvement for the operator

during the manufacturing of tubes.

Accessories are available, like an integrated saw, a de-burring device, a flaring tool and a

compression-fitting swaging tool.

Your benefits at a glance

Stable, flexible and economical

This ‘K’ series will win you over with its special stability and performance. Individual pieces and

small batches can be produced in an extremely economical manner with this machine concept.

The use of high-value components ensures the machine‘s durability.

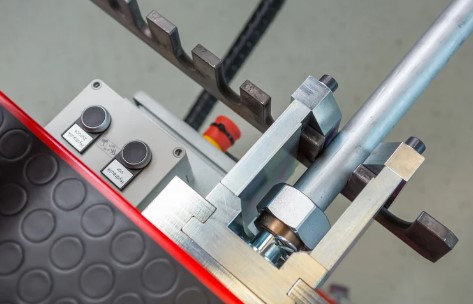

COLLET CHUCK

- For 360° rotation by scale, with 4 adjustable stops

- With chuck clamp for all sizes up to 3“

- Inclusive length stop device with scale and 4 adjustable stops

- Usable arbor length 20 ft

QUICK-ACTION CHUCK

- For holding individual collets (optional)

Your optional benefits at a glance

DE-BURRING MACHINE

The separation cut is made directly after the last bend. No further re-cutting is necessary.

Capacity:

* For tubes from 1/4“ – 1 5/8“

Machine equipment-/basic accessories:

* De-burring tools

* De-burring heads easily sharpened and adjusted

* Internal de-burring tool with 3 HSS edges

* External de-burring tool with 1 HSS edge

Carriage for cutting ring

pre-assembly & flaring

- For tubes from 1/4“ – 1 5/8“

- For pre-assembling single and multi bite rings according to DIN 2353

BENDING MANDRELS

- Bending mandrels in different contours or materials.

WIPER DIE

- Prevents the deformation in the form of wrinkles that occurs wh

Time- and cost-saving

- Fast set-up times due to swivel bridge, plugged tools and bayonet lock for the collet chuck.

A live or remote demonstration can

be arranged and is recommended

For details, we invite you to reach out to me

I’ll be your personal contact throughout your

onboarding enquiry with us.

Direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news message on to

team members / colleagues who you think may benefit.

Thank you in anticipation for your support.