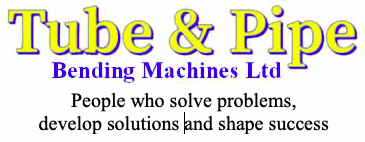

t bend – Mandrel Bending Machines with

servo-electric motors for better efficiency.

T BEND SERVO-ELECTRIC

The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For pipes with diameters from 1/4″ to 6″.

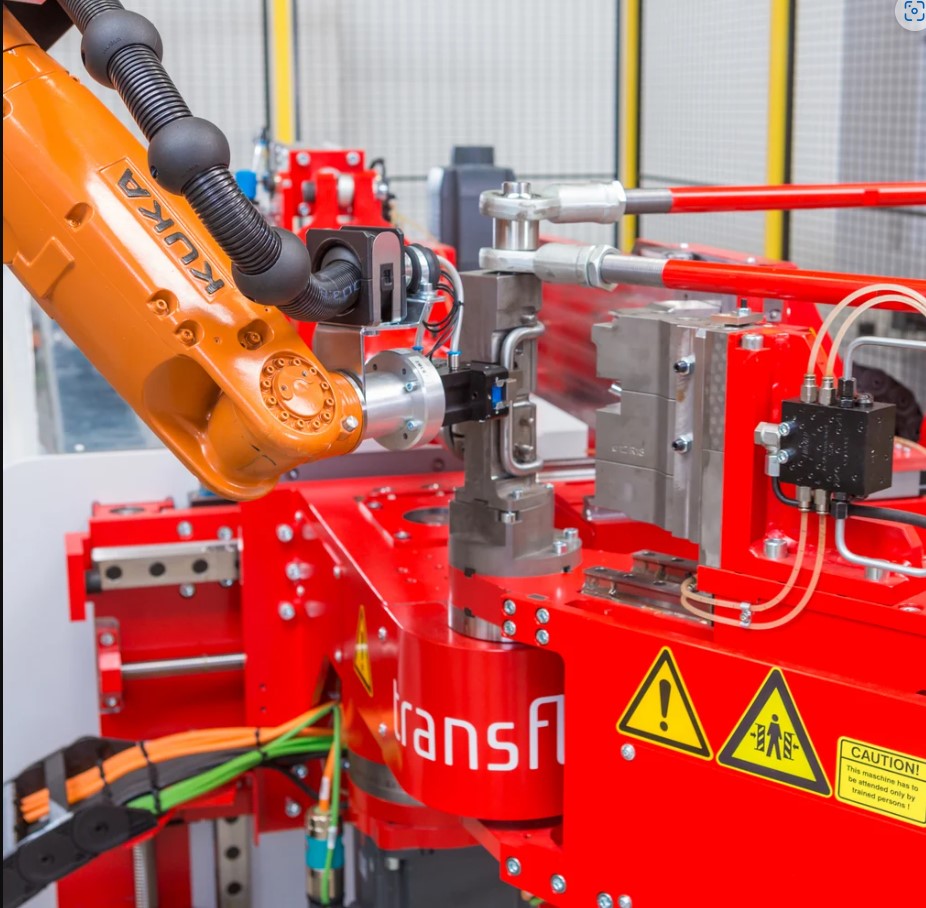

transfluid® t bend DB CNC-VE

All-electric CNC mandrel tube bending machines.

Family of nine

Full electric CNC-CV

mandrel tube bending machines

Complete with all the features you want

Capable of bending tube sizes:

22mm/od – 30mm/od – 42mm/od

50mm/od – 60mm/od – 80mm/od

100mm/od – 130mm/od – 150mm/od

See what you can do

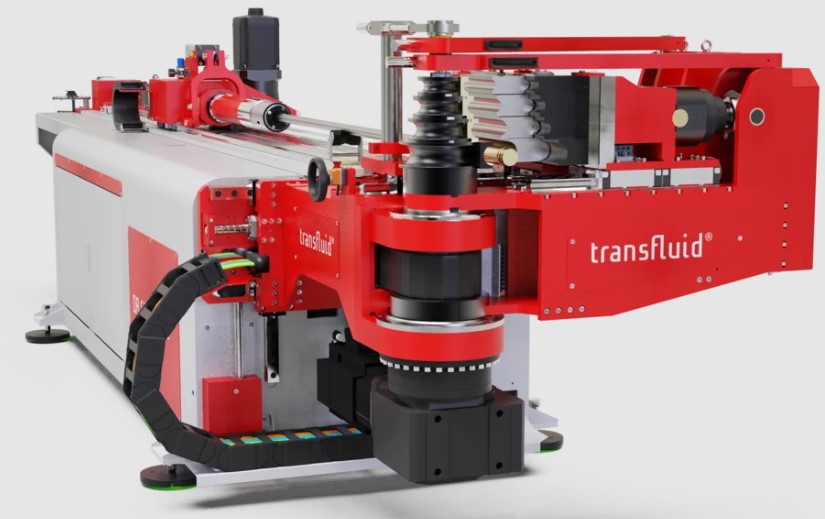

The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square,

rectangular, and other special profile shapes including solids. In addition, they are known for outstanding rigidity and

power which is unmatched in the market for this size of machines.

Regardless of the material, the end result is always perfect.

Our robust machine construction means customers have come to expect decades of heavy use.

This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program

in a Windows based, network ready operating system.

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for

bending on multiple levels with automated tool change makes it possible to achieve various radii

and the most complex geometries on tubes.

Also available with push bending function – the most complex bends become reality with great accuracy.

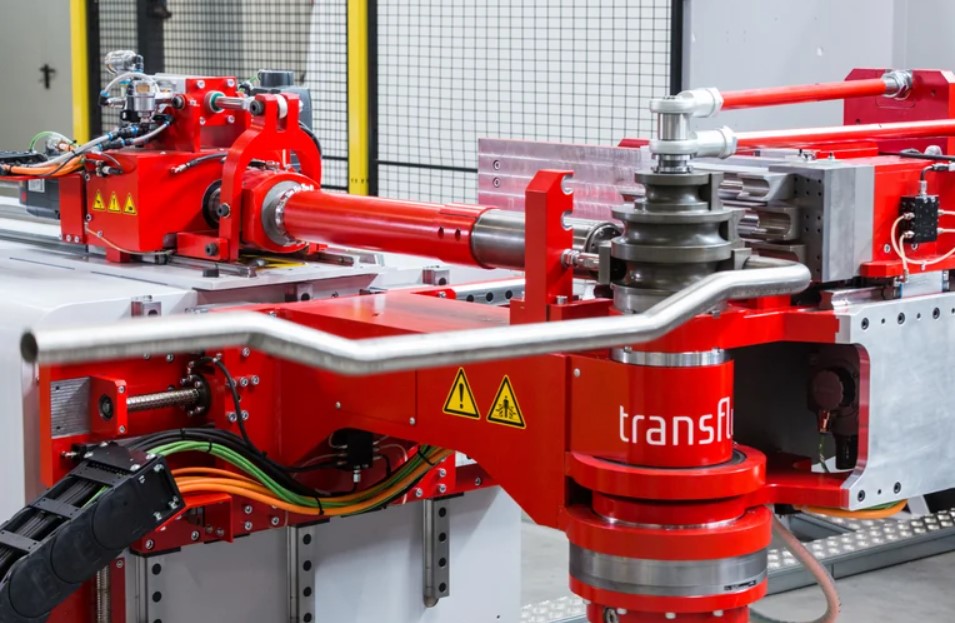

MULTILEVEL BENDING

Each bending head can be equipped with minimum two tool sets, e.g. with different bending radii or form-clamps, max. changing height for standard machine is 60 mm.

Bending tools for tubes with already formed tube ends.

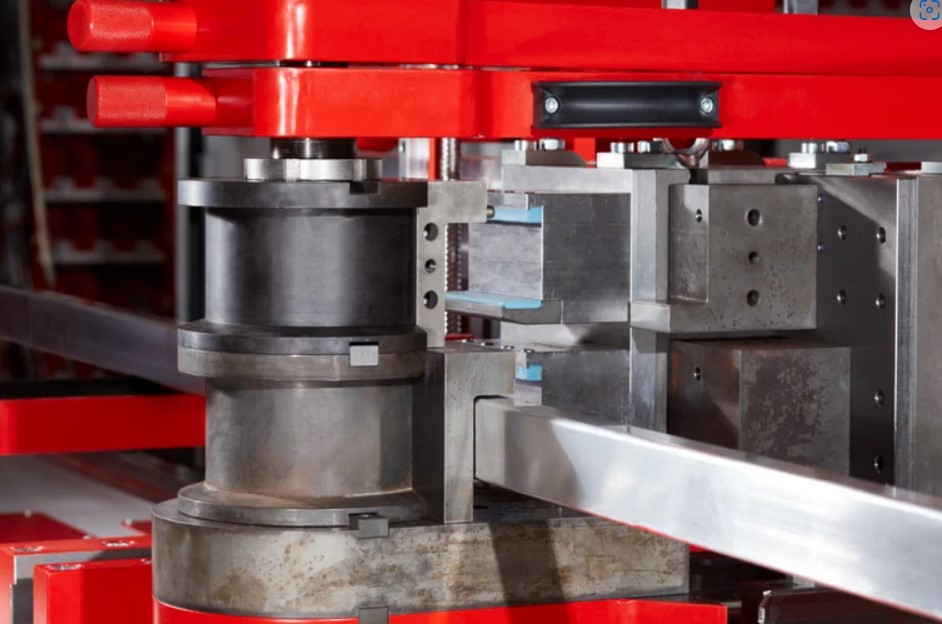

SOLID MATERIAL

Adaptation of the bending machine for bending busbars/ conductor rails/ flat conductors.

COST-EFFECTIVE MATERIAL LOADING

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length.

Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell.

External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible.

It will be my pleasure to assist you with your

Tube Bending and Processing challenges.

A live or remote demonstration can be

arranged and is recommended

Please direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news on to team

members / colleagues who you think may benefit.

Thank you in anticipation for your support