Transfluid’s family of four T BEND SERVO-ELECTRIC Bi-Directional (R / L) Mandrel tube bending machines

Featuring the latest CNC control and software, making the most complex tubular bends a reality with great accuracy

Capable of bending tube sizes:

4 – 22 mm/od

4 – 30 mm/od

6 – 42 mm/od

6 – 70 mm/od

We have the right solutions

With more than 30 years experience and many projects successfully completed

Ignite your imagination…

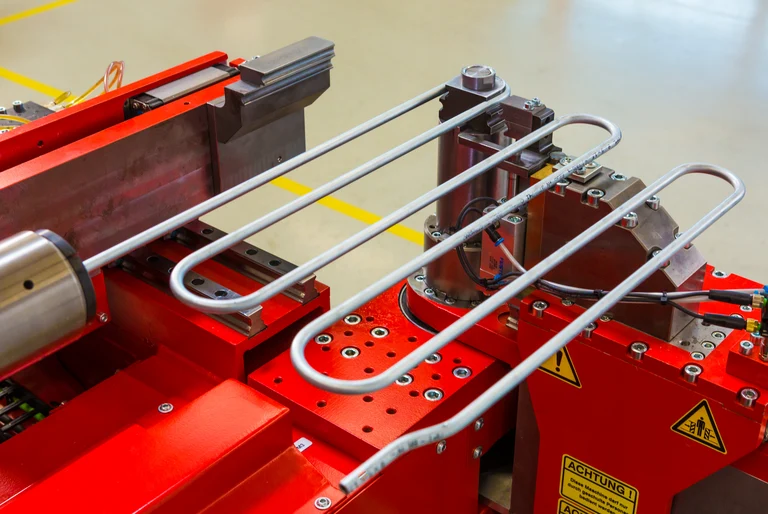

transfluid® t bend DB CNC-R/L – ECONOMICAL – AUTOMATED – PROCESSES

With our bi-directional clockwise / counterclockwise bending machines the most complex bends

become reality with great accuracy.

The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically,

including 360° rotation axis for a change of bending direction (right- or left-hand).

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.

Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii

and the most complex tubular geometries.

Our robust machine construction means customers have come to expect decades of heavy use.

This machine is supplied with an easy-to-use Siemens CNC control system, which utilises an intuitive

program in a network ready Windows based operating system.

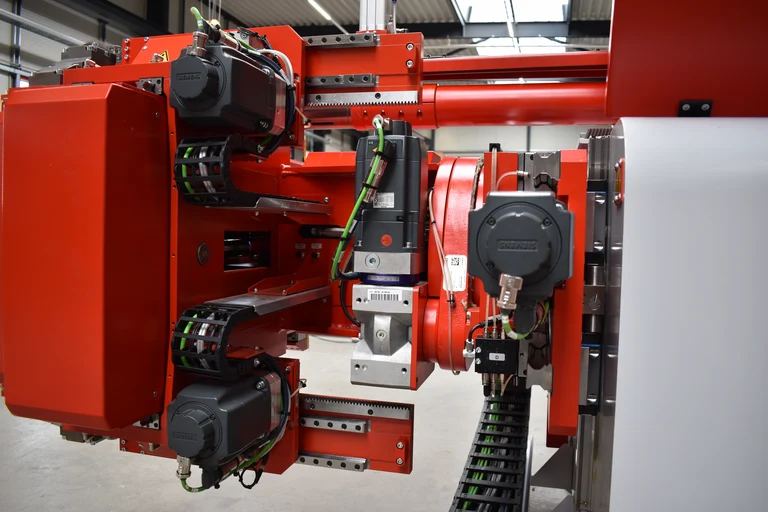

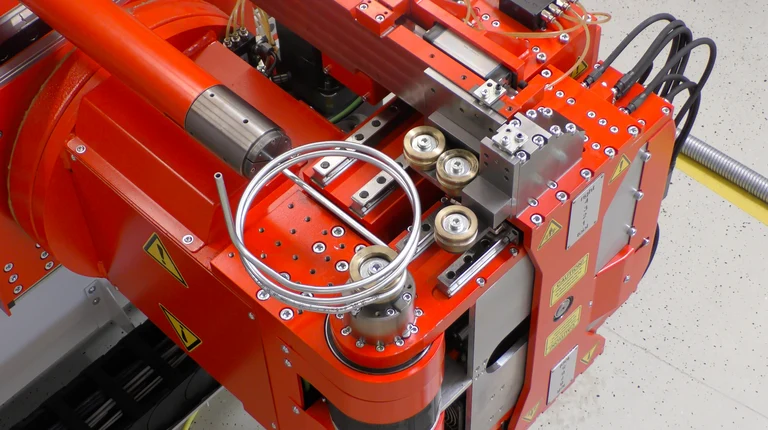

THE 360° BENDING HEAD

The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand).

FREE BENDING DIRECTION

Positioning of bending head via combined diagonal and rotation axis, right-and-left-hand bending in one operation.

BENDING MANDRELS

Bending mandrels in different contours or materials.

FULLY ELECTRIC

100% electric drive of all 11 axes. Compared to hydraulic machines, energy savings of up to 50% can be achieved.

CONTROL UNIT

The control unit is equipped with high-quality electronic components from leading suppliers. This ensures a long service life and a reliable supply of spare parts over a long period of time.

BOOSTING FUNCTION & PUSH BENDING

The collet is equipped with a powerful motor for push bending. Especially when bending thin-walled materials and very small bend radii this feature can improve the bend quality, and the wall thinning can be reduced.

Special tooling is available for push bending large radii.

We have the right solutions

With more than 30 years experience and many projects successfully completed

Ignite your imagination…

It will be my pleasure to assist you with your

tube bending / processing challenges

There are loads of benefits to unpack

A live or remote demonstration can

be arranged and is recommended

Direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news message on to

team members / colleagues who you think may benefit.

Thank you in anticipation for your support