t form – Type UMR rollforming machines produces

perfect mirror-like sealing surfaces

Easy visualisation via touch panel

For the production of 37°, 45°, 90° and ORFS flanging

Extremely short clamping lengths (from 1xD)

Simple, fast and easily accessible tool change

Feeding of ORFS o-rings

transfluid® t form UMR ROLLFORMING MACHINES

Powerful and fast forming.

UMR tube forming machines use smart operating technology with many predefined settings that can be

retrieved automatically to achieve perfect mirror-like surfaces.

When producing flares with 20°-90° angles, with a clamping length of 1 x D, the machine achieves perfect sealing

surfaces. Flaring up to 90° can be produced in a single cycle. Tools can be changed extremely quickly. With the

appropriate tools, the machine can also close tube ends.

Create safe, effective and cost-efficient ORFS connections

With the semi-automatic ORFS ring feeder, transfluid has developed a cost-effective solution for the safe and effective

production of small, medium and even large batch sizes.

Feeding via a magazine with a poka-yoke system eliminates incorrect assembly, ensuring consistently high quality.

Short cycle times make assembly more economical and the automated solution significantly reduces the workload of

the machine operator. Machine instruction and training can be reduced to a minimum.

EASY CONTROL VIA TOUCH PANEL

Setting of all parameters centrally in the machine control system, controlled positioning of the

forming axis and the stop position.

The UMR is equipped with a completely electronic preselection of the flanging geometry. The stop position and all

strokes and machining operations are servo-electrically controlled and can be called up via a touch panel.

Exact machining time is determined by the material used and the shape to be implemented. The machine

carries out the processing automatically, it is possible to call up the tube size along with the necessary process

parameters. In individual cases, the clamping lengths for machining are 1 to 1.5 x the pipe diameter.

Time saving. Our new generation of t form UMR 628, 642 and 2090 machines reduces the set-up time when

changing the tools and the operator can set up the machine in less than three minutes.

PERFECT SEALING SURFACES

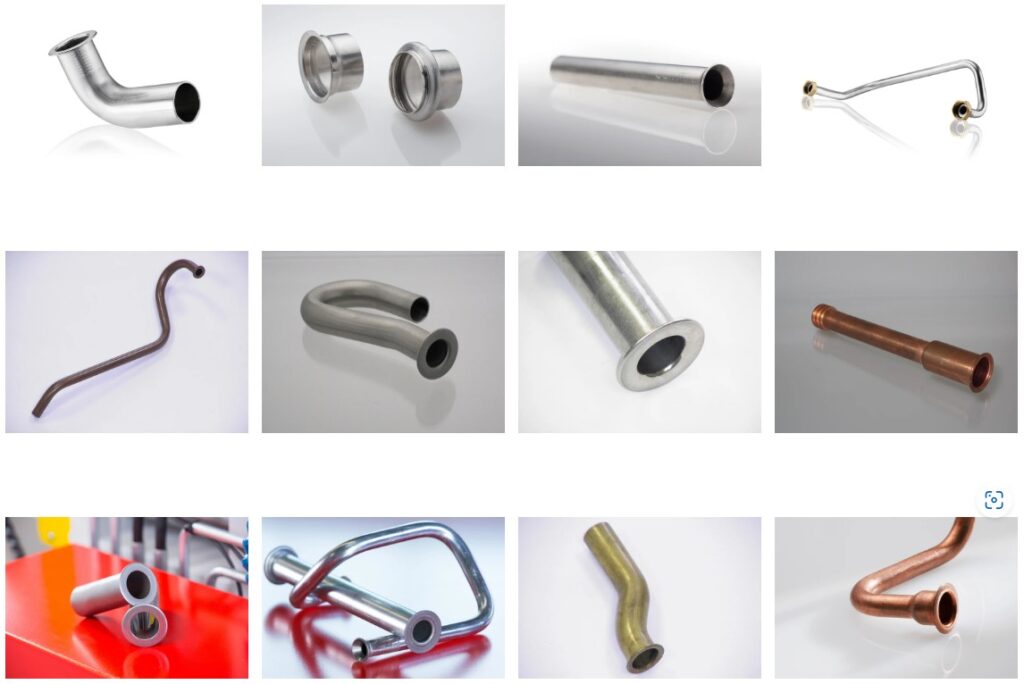

See what you can do…

AUTOMATION IS THE WAY FORWARD

It will be my pleasure to assist you with your

tube processing challenges.

A live or remote demonstration can be

arranged and is recommended

Please direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news on to team

members / colleagues who you think may benefit.

Thank you in anticipation for your support.