HVACR

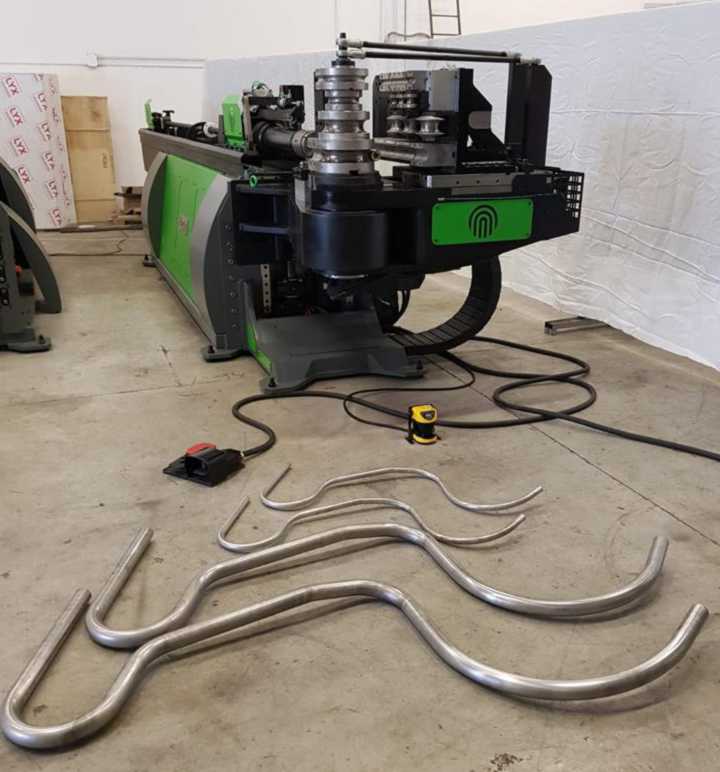

Specialist suppliers of tube processing machinery and related equipment for the:

Heating, Ventilation, Air Conditioning, and Refrigeration Industries

Flecte is the No:1 choice

Different Materials – Different Problems

Different Solutions

Capable of bending tube sizes From

6mm/od up to 150mm/od

Multi-stack, fixed radius and variable radius within the same bending process

Come direct

There are a load of benefits to unpack

We offer complete consultation and step by step advice to accompany

your project from planning through to commissioning

A live or remote demonstration can be arranged

and is recommended

Direct dial, text or

WhatsApp:

John Owen

07776 213919

International DD: 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news on to team

members / colleagues who you think may benefit.

Thank you in anticipation for your support.