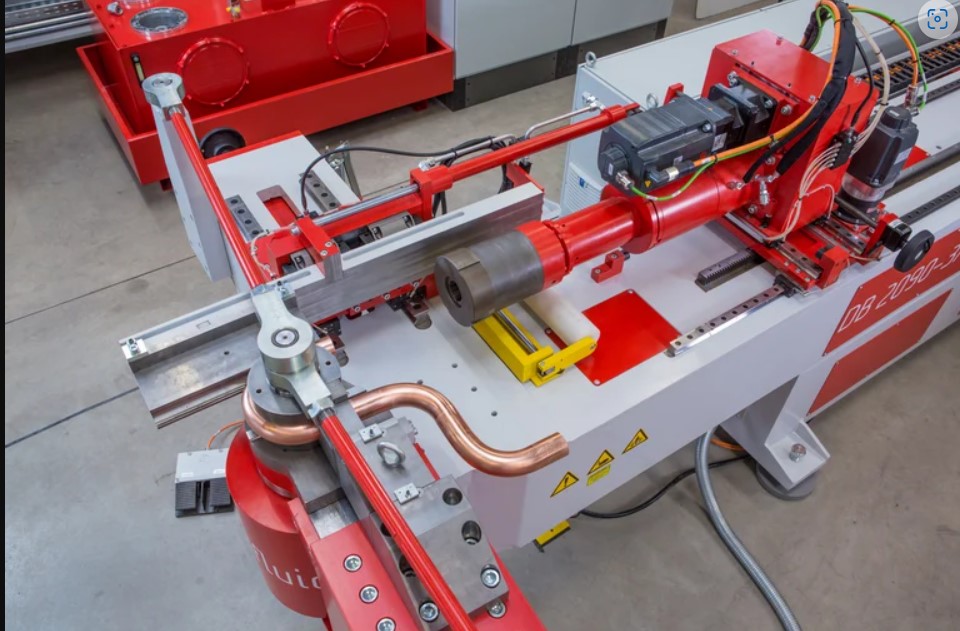

t bend – Heavy duty mandrel tube bending machines with

servo-hydraulic motors for guaranteed extraordinary bending quality.

Accuracy and repeatability allow for the rail to be used as a template, greatly reducing layout time on the bench

Energy savings up to 70% by control of the hydraulic pump via a servo motor.

Typical bend time for a 4-bend wall rail is less than 2 minutes

Bends to the same radius as purchased elbows, so when an elbow is still required, the bends look exactly the same

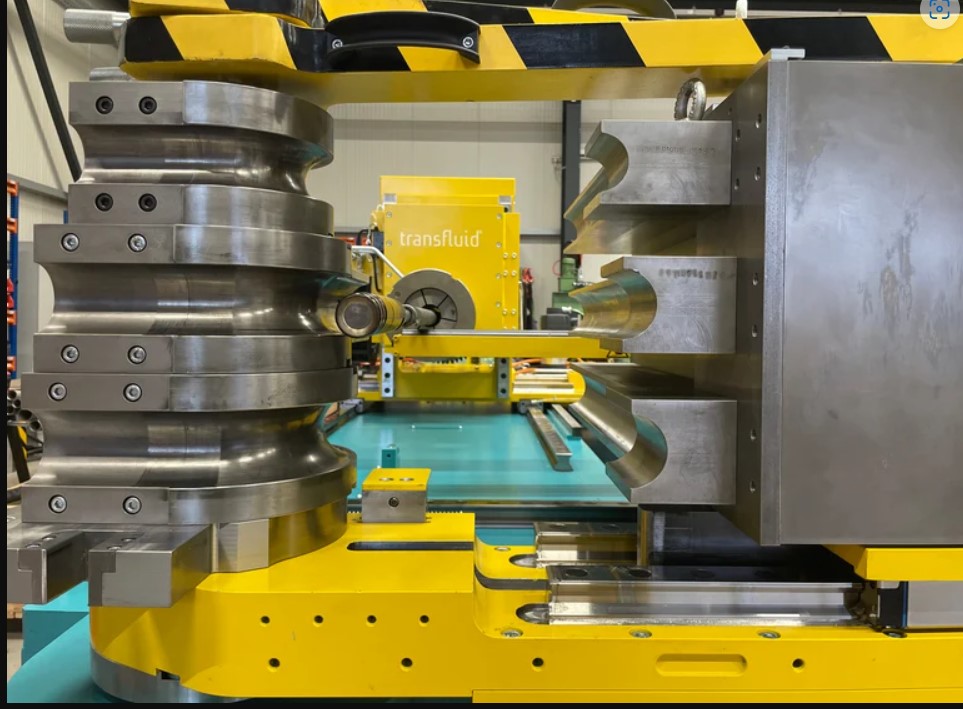

transfluid® t bend DB 3A-CNC

The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality.

The machine meets all industry standards and exceeds customer expectations.

MULTI-Stack bending

Each bending head can be equipped with minimum two tool sets, e.g. with different bending radii or form-clamps, max. changing height for standard machine is 60 mm.

Bending tools for tubes with already formed tube ends.

Innovative Servo-Hydraulic System – Energy savings up to 70% by control of the hydraulic pump via a servo motor.

On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and

increasing lifecycle of all hydraulic components.

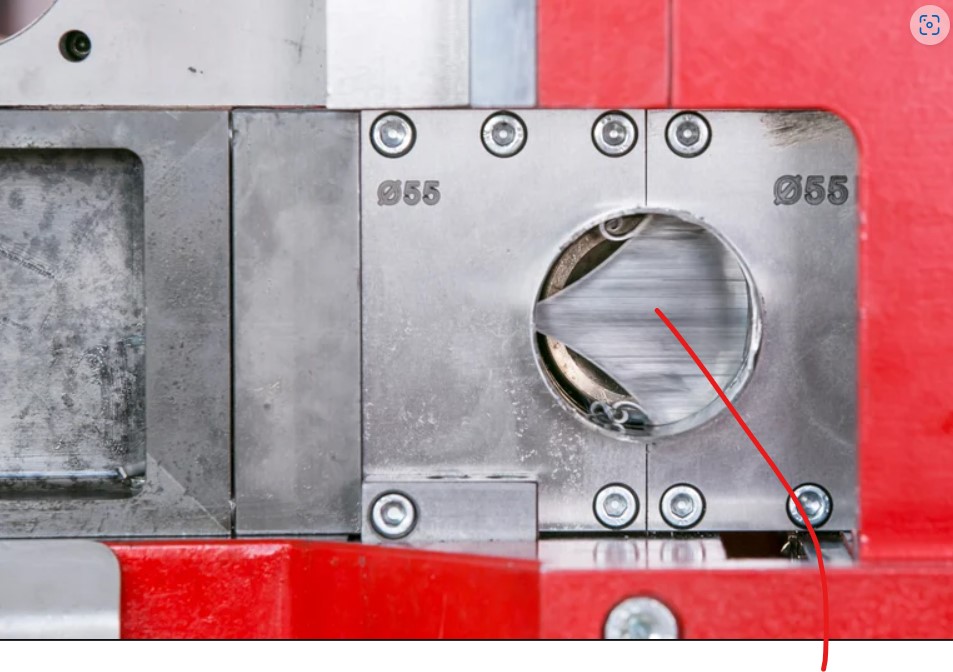

CUTTING DURING BENDING PROZESS

The separation cut is made directly after the last bend. No further re-cutting is necessary.

The Software – Simple and intuitive manual input by machine operator with 3D graphical display.

Import module allows easy import of step files from Tekla and other detailing systems.

SOLID MATERIAL

Adaptation of the bending machine for bending busbars/ conductor rails/ flat conductors.

Ignite your imagination – We have the right solutions

With more than 30 years experience and many projects successfully completed

It will be my pleasure to assist you with your

Tube Bending and Processing challenges.

A live or remote demonstration can be

arranged and is recommended

Please direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news on to team

members / colleagues who you think may benefit.

Thank you in anticipation for your support