Transfluid t form – combination end forming machines

combine the benefits of axial and rollforming

Complex forming geometries

Up to 6 additional forming steps

Additional rollforming stations

Multiple forming possibilities

Short clamping length

Quality benefits thanks to just one clamping step

COMBINATION MACHINES

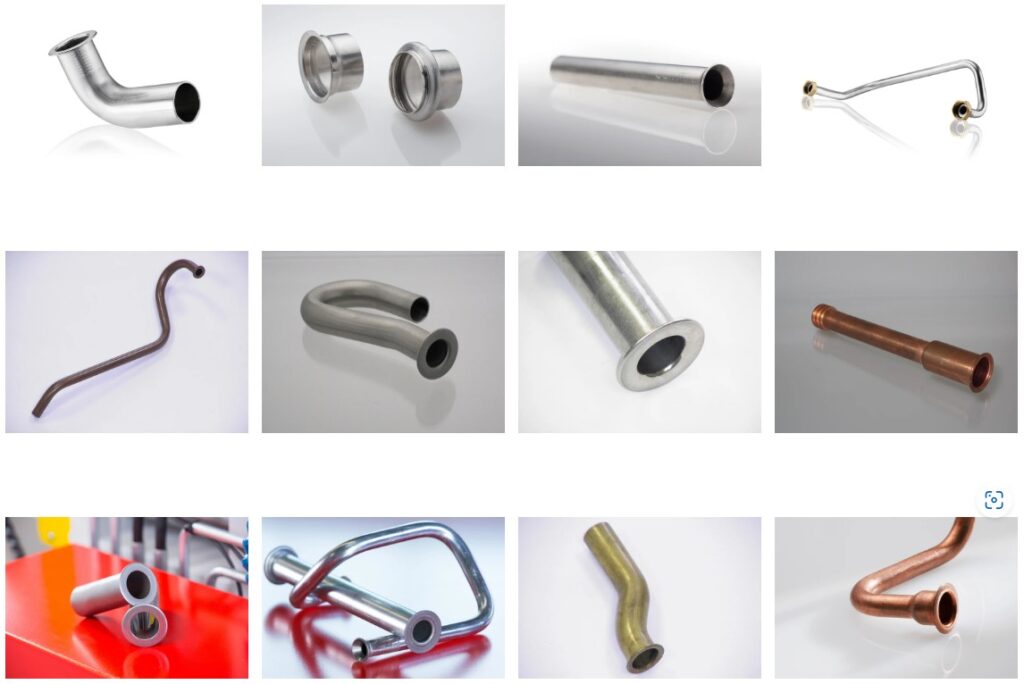

Transfluid’s combination tube end forming machines is the perfect solution for forming Highly complex, demanding

geometries in one work sequence: in our combination machines we have combined the benefits of axial and

rollforming in one single system. Further processing step can be integrated without any problems.

Intelligently Recombined: Axial and Rolling:

Transfluid’s new generation of combination machines can form parts that previously had to be turned. A major cost

saving, replacing high-cost, expensive turned parts eliminating the need for elaborate soldering or welding.

See what you can do…

A strong partnership: axial forming and rollforming

Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming

steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit.

The horizontal clamping system makes the processing of bent tube geometries possible.

See what you can do…

Transfluid’s AUTOMATION IS THE WAY FORWARD

It will be my pleasure to assist you with your

tube processing challenges.

A live or remote demonstration can be

arranged and is recommended

Please direct dial, text or

WhatsApp me:

John Owen

UK: 07776 213919

Int’ 0044 7776 213919

Or, Use the form to join the conversation

Please forward this e-news on to team

members / colleagues who you think may benefit.

Thank you in anticipation for your support