FREE Definitive Buyers Guide Includes the missing piece's in the buying process For buyers of production tube bending equipment Nine biggest problems and their solutions... If you know exactly what you're looking for... Pro's and Con's of NC or CNC... New or Refurbished? Download your FREE PDF copy of the Definitive Buyers Guide Thank you for downloading your FREE PDF copy of: the Definitive Buyers Guide

All too often, CNC Tube Bending machines are discarded for the simple reason of no support for old, often proprietary control systems, obsolete hardware, and dated software. Mechanical elements such as bearings, bushings, linkages, gears, ball-screws, and hydraulics are easily repaired or replaced but the electronics are not! Knowing the weakness and shortcomings of most manufacturers and suppliers we formed a team of professional engineers with a vast wealth of experience in CNC tube, wire, and profile bending: And We will happily offer to providegood old fashioned.Service Support Backup For All makes of tube bending / forming machines and related equipment,…

As an owner of production tube bending equipment, you will at some point have to find solutions to maintenance problems particularly whilst in the middle of a production run. Here is a list of the seven biggest problems most people experience with their CNC tube bending machines. Have you ever lost production simply because you had problems with a touchscreen, a disk drive, a monitor, a keyboard failure, etc.? Have you also ever wondered why a CNC Tube Bending Machine has a permanently attached HMI? (Human Machine Interface) Have you ever had to call on your company's IT personnel to…

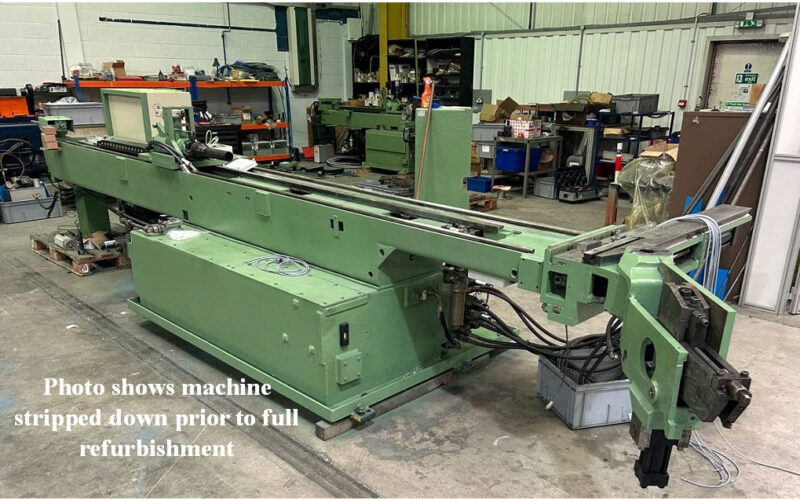

Photograph of machine prior to being rebuiltNow rebuilt and Available Immediately. General Information Addison DB40 Twin Stack CNC Bending Machine Capable of bending tube sizes up to: 40mm/od x 3mm/wt 2 Tooling Stack Hydraulic Proportional C Axis (Bending) Electric Servo Motor Y Axis (Positioning) Electric Servo Motor B Axis (Rotation) Hydraulic Proportional X Axis (Radius Change) Pneumatic stack change Hydraulic clamping Hydraulic pressure die Hydraulic pressure slide Hydraulic mandrel Pneumatic collet We have already stripped the machine down to it's bear chassis and rebuilt it back to full production capability. Scope of works: Mechanical refurbishment of machine Complete electrical re-wire…

Craig started his illustrious career with Addison Tube Forming Ltd in 1981 and was soon promoted to technical sales and service engineer to launch Addison products in the USA. His career has taken him around the world gaining invaluable experience. A brief history of the evolution of Phenix.In 1987, Phenix was born and was the worlds first all-digital-motion CNC / NC control system, specifically for tube bending. This was also the first ever to feature the very robust capacitive touch-screen technology and graphical user interface (GUI). Our first major customer was, at the time, the world's No:1 car producer. In…

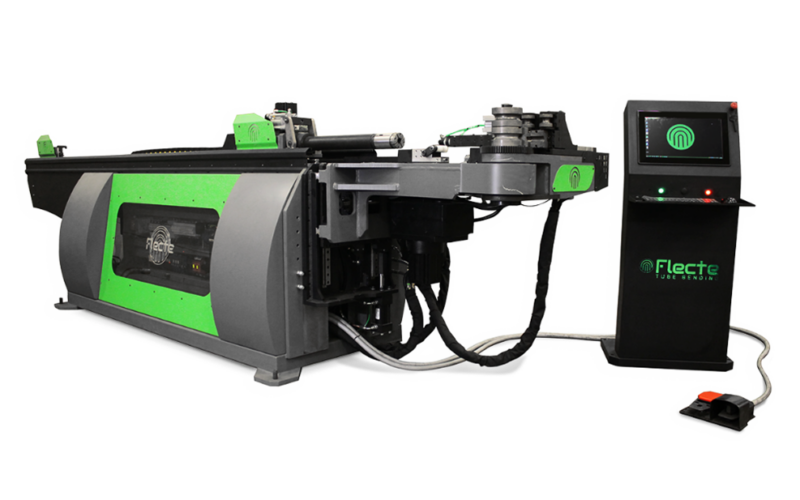

FlecteGreat Value Best in Class family of CNC mandrel tube bending machines VEX 905 Hybrid 90mm/od mandrel tube bending machine Multiple stacks – 5 CNC axis For a variety of tube profiles with fixed radius mandrel bending and capable of variable radius roll bending in the same bending process. See full technical specification below Optional extras include: auto load / off load systems - Tooling Full UK parts and labour warranty, support and back up – “We look after our customers“ https://youtu.be/zL1ZCavmEhQ?rel=0 Technical Specification Maximum Tube Diameter90Number of Electric Servo Axis5Number of Tooling StacksMultipleMachine Length7200Machine Width1360Machine Height1600Machine Weight6000 kgElectrical Power Consumption35 KwMaximum…

FlecteGreat Value Best in Class family of CNC mandrel tube bending machines VEX 455 Hybrid mandrel tube bending machine capable of bending tube sizes up to: 45mm/od mandrel tube bending machine Multiple stacks – 5 CNC axes For a variety of tube profiles with fixed radius mandrel bending and capable of variable radius roll bending in the same bending process. See full technical specification below Optional extras include: auto load / off load systems - Tooling Full UK parts and labour warranty, support and back up – “We look after our customers“ https://youtu.be/TnA1tB-eteo?rel=0 Technical Specification Maximum Tube Diameter45Number of Electric Servo Axis5Number…

FlecteGreat Value Best in Class family of CNC mandrel tube bending machines VEX 454 Hybrid mandrel tube bending machine capable of bending tube sizes up to: 45mm/od. 4 CNC axes For a variety of tube profiles with fixed radius mandrel bending and / or capable of variable radius roll bending. See full technical specification below Optional extras include: auto load / off load systems - Tooling Full UK parts and labour warranty, support and back up – “We look after our customers“ https://youtu.be/DuW19SHKjGY?rel=0 Technical Specification Maximum Tube Diameter45Number of Electric Servo Axis4Number of Tooling StacksDoubleMachine Length5250Machine Width1200Machine Height1600Machine Weight2450 kgElectrical Power Consumption17.5…

FlecteGreat Value Best in Class family of CNC mandrel tube bending machines VEX 453 Full electric 45mm/od mandrel tube bending machine Multiple stacks – 3 CNC axis For a variety of tube profiles with fixed radius mandrel bending. See full technical specification below Optional extras include: auto load / off load systems - Tooling Full UK parts and labour warranty, support and back up – “We look after our customers“ https://youtu.be/F4LOQffE_Vk?rel=0 Technical Specification Maximum Tube Diameter45Number of Electric Servo Axis3Number of Tooling StacksSingleMachine Length5250Machine Width1200Machine Height1600Machine Weight2350 kgElectrical Power Consumption15 KwMaximum Tube Length Over Mandrel4600Maximum Bend Centre Line Radius125Maximum Tube…

Whether you’re completely new to CNC tube bending or one of our tenth-time returning customers. You will be made very welcome when you visit our prestigious UK showroom for a deep dive live or remote demonstration Flecte, lead the way in CNC tube bending technology with a family of 7 High Performance CNC machines to choose from and a support system that you can rely on when you need it. Great value Flecte Deluxe range of CNC mandrel tube bending machines. Every Flecte machine benefits from innovative design, engineering to the highest specifications and assembly by highly trained technicians. Machines designed to…