Addison DB76-CNC Full 3 axes CNC mandrel tube bending machineCapable of bending tube sizes up to: 76mm/od x 3mm/wtComplete with drop-away clamp, ideal for the fast moving high production tube bending industry Download Addison official full machine specifications Game Changer. This impressive quality mandrel tube bending machine is soon to be Recharged and Renewed to Phenix the Major 21st Century ‘Revolutionary‘ CNC control and software. Phenix makes tube bending machines work: Better – Faster – Smarter! Unlocking the power of digital ensuring many years of high performance profitable production life. See what our customers have to say Available around three working weeks from date of order.…

It's FREE to join Lower your utility bills. Saving on your household bills is simple when you bundle energy, broadband, mobile and insurance into one monthly bill. Learn more

Craft a Strategic Roadmap: Develop a clear plan outlining the specific actions you need to take to bridge the gap. This roadmap encompasses tangible steps, timelines, and resource allocation strategies. Professionals and wealthy people use this income strategy Professional income strategies - The Well 'V' The Stream explained

The 'A' Team for Service Support Backup The problem is all too often thesame old, same old You buy a tube bending machineonly to find after sales backup isvirtually non-existent!😟 The 'A' team for Service Support Backup Different Materials,Different Problems,Different Solutions How different materials behave during tube bending process. Each material has its own characteristics, specific strengths and weaknesses and its own problems and critical issues when bending. Different Materials, Different Problems, Different Solutions Tube & Pipe Bending Machines Ltd Our Tube Processing Mission for 2025 and beyond Whatever you think of new year's resolutions, there's no denying that January…

Includes the missing piece's in the buying process For buyers of production tube bending equipment Nine biggest problems and their solutions... If you know exactly what you're looking for... Pro's and Con's of NC or CNC... New or Refurbished? Essential reading - Just complete the form to receive your FREE PDF copy of the buyers guide Essential reading Thank you for requesting your FREE copy of the Definitive Buyers Guide. Your copy will be in your inbox very soon, please check your spam folder too, just in case!

FREE Definitive Buyers Guide Includes the missing piece's in the buying process For buyers of production tube bending equipment Nine biggest problems and their solutions... If you know exactly what you're looking for... Pro's and Con's of NC or CNC... New or Refurbished? Download your FREE PDF copy of the Definitive Buyers Guide Thank you for downloading your FREE PDF copy of: the Definitive Buyers Guide

All too often, CNC Tube Bending machines are discarded for the simple reason of no support for old, often proprietary control systems, obsolete hardware, and dated software. Mechanical elements such as bearings, bushings, linkages, gears, ball-screws, and hydraulics are easily repaired or replaced but the electronics are not! Knowing the weakness and shortcomings of most manufacturers and suppliers we formed a team of professional engineers with a vast wealth of experience in CNC tube, wire, and profile bending: And We will happily offer to providegood old fashioned.Service Support Backup For All makes of tube bending / forming machines and related equipment,…

As an owner of production tube bending equipment, you will at some point have to find solutions to maintenance problems particularly whilst in the middle of a production run. Here is a list of the seven biggest problems most people experience with their CNC tube bending machines. Have you ever lost production simply because you had problems with a touchscreen, a disk drive, a monitor, a keyboard failure, etc.? Have you also ever wondered why a CNC Tube Bending Machine has a permanently attached HMI? (Human Machine Interface) Have you ever had to call on your company's IT personnel to…

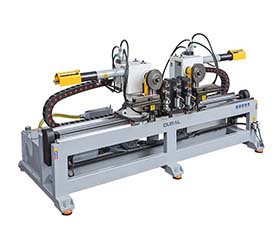

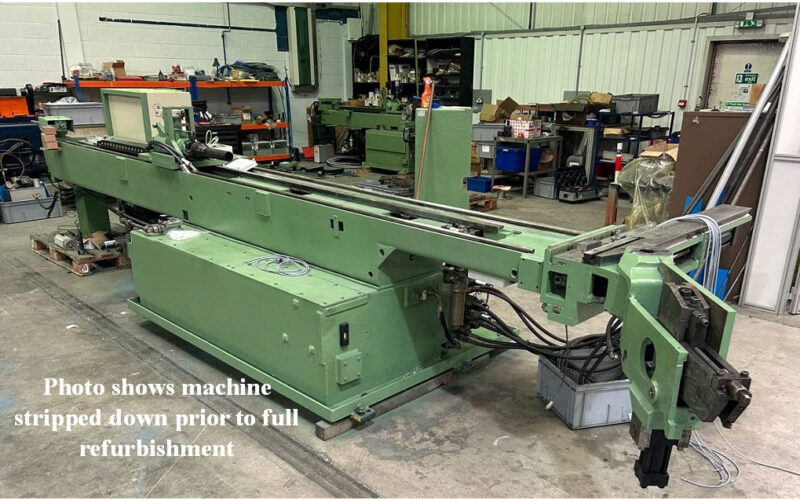

Photograph of machine prior to being rebuiltNow rebuilt and Available Immediately. General information Addison DB40 Twin Stack CNC Bending Machine Capable of bending tube sizes up to: 40mm/od x 3mm/wt 2 Tooling Stack Hydraulic Proportional C Axis (Bending) Electric Servo Motor Y Axis (Positioning) Electric Servo Motor B Axis (Rotation) Hydraulic Proportional X Axis (Radius Change) Pneumatic stack change Hydraulic clamping Hydraulic pressure die Hydraulic pressure slide Hydraulic mandrel Pneumatic collet Scope of works: Mechanical refurbishment of machine Complete electrical re-wire New Industrial PC (Beckhoff) New operator console New touch screen New servo motors & drives (Lenze) New bend axis…