The ‘A’ Team for

Service Support Backup

The problem is all too often the

same old, same old

You buy a tube bending machine

only to find after sales backup is

virtually non-existent!😟

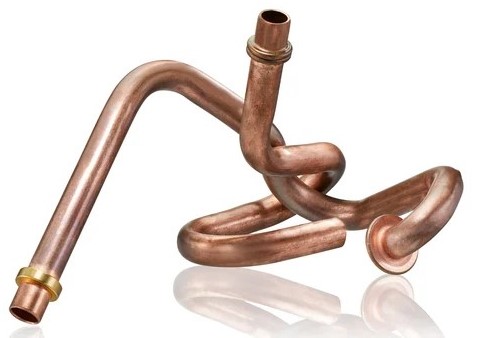

Different Materials,

Different Problems,

Different Solutions

How different materials behave during tube bending process. Each material has its own characteristics, specific strengths and weaknesses and its own problems and critical issues when bending.

Tube & Pipe

Bending Machines Ltd

Our Tube Processing Mission for

2025 and beyond

Whatever you think of new year’s resolutions, there’s no denying that January can often make us sharpen our focus on what we want to achieve in the new year

We’ve been thinking a lot about YOU and

Our Tube Processing Mission for

2025 and beyond

Ship Building and Plant Building

Large pipe bending machines

in use all around the world.

Solutions for pipe sizes up to 150mm/od .

In the past, large pipes were mostly welded. However, it has been recognised in the shipbuilding industry that our tube bending technology enables much more efficient processing.

Solutions that significantly reduce manufacturing costs and create a time advantage of up to 60%. An unbeatable advantage on international markets.

Furniture – Display – Medical Aides

Machines and systems built to meet

the most complex challenging designs

Bending tubes in round, oval, square, rectangular, and other special profile shapes.

Known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Hydraulics Industry

BENDING AND FORMING TUBES FOR

HIGHLY DYNAMIC STRESS

To produce reliable connections in the hydraulic area, it is often necessary – not to mention most important – to produce 37°- and 90° flanges with short clamping lengths.

HVACR

Heating, Ventilation, Air Conditioning, and Refrigeration

Industries

Offering customers in the HVACR technology sector many important advantages. The biggest one, however, is the comprehensive portfolio of machines for tube production.

Automotive and Aerospace Technology

Solving complex problems ‘easily’

Sophisticated and precisely bent tubes for the numerous functional areas of a vehicle or aircraft such as brakes, air conditioning,exhaust system and steering, help you to optimally meet the high demands placed on your product.

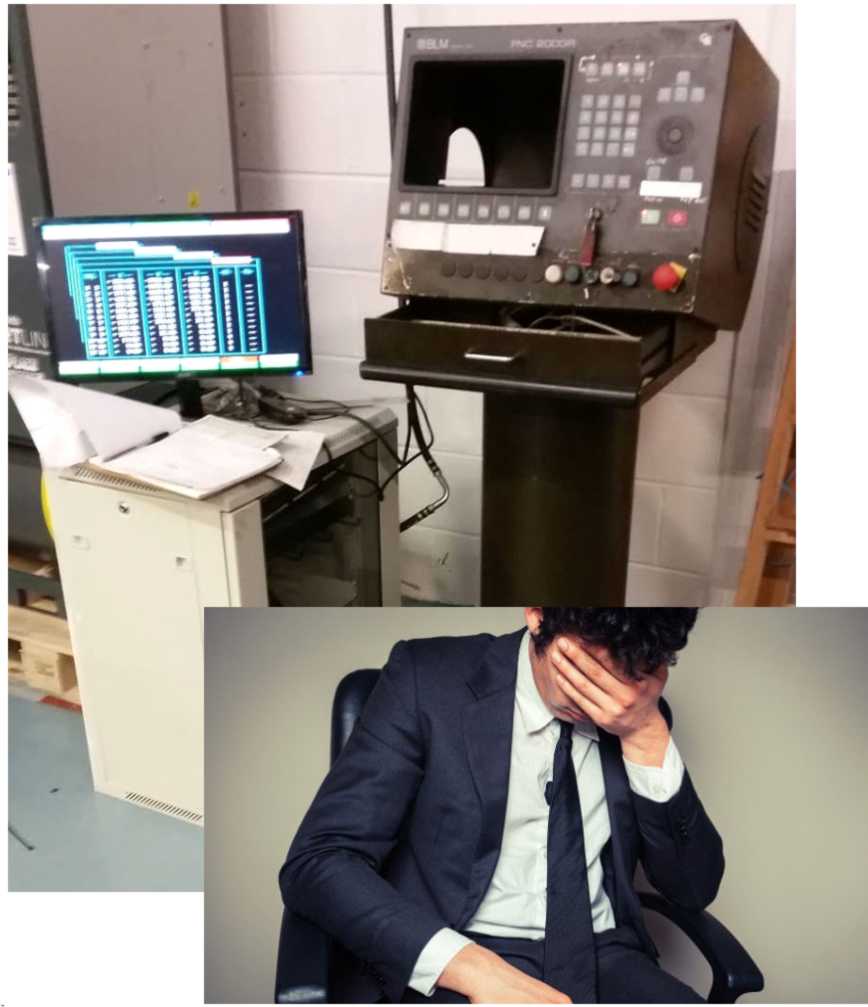

Business owners

Production Managers and Directors

Does this look familiar?

Dead touch screen

Reliability issues

Quality of bend issues

Setting up problems

Production too slow

Repeatability all over the place

Problems – Problems

Problems

They never seems to end

Time is running out before production

problems start to affect your profitability

Life can be stressful enough without worrying whether your tube bending machine is about to give up on you especially when you are in the middle of a production run

When your budget doesn’t allow for a new machine, but your existing machines control and software is faulty, unreliable, virtually scrap.

Where can you go from here??

Best Practice

Upgrade to Phenix

And raises up your tube bending machines to become:

High Performance

‘Majestic’

Production Machines

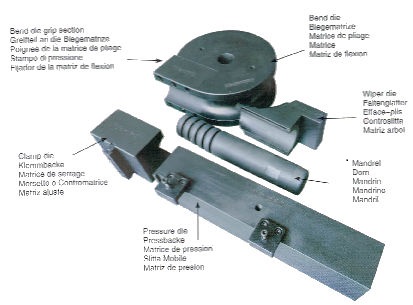

How to Bend Tube to get the best wrinkle free results

Have you ever tried to bend tube and every time it turns out creased and wrinkled?

Bending a tube requires accuracy and precision. Every detail matters when making a smooth bend. Choosing the correct size bender, the correct tooling set, and the correct style of bender are all crucial factors.

Craig Webster CNC tube bending Superfast Software Specialist

Craig started his illustrious career with Addison Tube Forming Ltd in 1981 and was soon promoted to technical sales and service engineer to launch Addison products in the USA. His career has taken him around the world gaining invaluable experience.

Phenix-it Revolutionary CNC Controls and Software

Phenix is a Major 21st Century ‘Revolutionary‘ Game Changer

A Revolutionary, Open Source and Expandable, Efficient and Economical Intuitive System that unlocks the power of digital on your old, out of warranty CNC & NC tube bending machine/s.

The art of mandrel tube bending

The full Turn-Key package. If you are purchasing or have purchased a tube bending machine the following information will guide you on your way to manufacturing quality components. The main ingredients to manufacturing a superior quality component are. Tooling, Setting and a little splash of Lubricant.

How to bend tube

Have you ever tried to bend tube and every time it turns out creased and wrinkled? Bending a tube requires accuracy and precision. Every detail matters when making a smooth bend. Choosing the correct size bender, the correct tooling set, and the correct style of bender are all crucial factors.