Have you ever tried to bend tube and every time it turns out creased and wrinkled? Bending a tube requires accuracy and precision. Every detail matters when making a smooth bend. Choosing the correct size bender, the correct tooling set, and the correct style of bender are all crucial factors. A mandrel tube bending machine that firmly clamps the material is the best options in achieving consistent quality bends. Mandrel tube benders form the tube by drawing it over a mandrel and around the bend die. The material is clamped tightly to prevent slippage, to create a consistently smooth high-quality bend.…

All too often, CNC Tube Bending machines are discarded for the simple reason of no support for old, often proprietary control systems, obsolete hardware, and dated software. Mechanical elements such as bearings, bushings, linkages, gears, ball-screws, and hydraulics are easily repaired or replaced but the electronics are not! Knowing the weakness and shortcomings of most manufacturers and suppliers we formed a team of professional engineers with a vast wealth of experience in CNC tube, wire, and profile bending: And We will happily offer to providegood old fashioned.Service Support Backup For All makes of tube bending / forming machines and related equipment,…

As an owner of production tube bending equipment, you will at some point have to find solutions to maintenance problems particularly whilst in the middle of a production run. Here is a list of the seven biggest problems most people experience with their CNC tube bending machines. Have you ever lost production simply because you had problems with a touchscreen, a disk drive, a monitor, a keyboard failure, etc.? Have you also ever wondered why a CNC Tube Bending Machine has a permanently attached HMI? (Human Machine Interface) Have you ever had to call on your company's IT personnel to…

We will happily offer to provide Interlinked good old fashionedService Support Backup after care packages For All makes of tube bending machines and, related equipment plus... Onsite service, support, when you need it for machine breakdowns, operator training, re-control upgrades, plus... On-going - Best in Class full machine 'Health-Care Backup Package' for all your tube bending end-forming and all cell related equipment. Taking the pressure off Knowing the weakness and shortcomings of most manufacturers and suppliers we formed a team of professional engineers with a vast wealth of experience in CNC tube, wire, and profile bending. Combine all the above with…

Craig started his illustrious career with Addison Tube Forming Ltd in 1981 and was soon promoted to technical sales and service engineer to launch Addison products in the USA. His career has taken him around the world gaining invaluable experience. A brief history of the evolution of Phenix.In 1987, Phenix was born and was the worlds first all-digital-motion CNC / NC control system, specifically for tube bending. This was also the first ever to feature the very robust capacitive touch-screen technology and graphical user interface (GUI). Our first major customer was, at the time, the world's No:1 car producer. In…

Interlinked leading edge philosophy Get your FREE PDF copy of the Buyers Guide Knowing the weakness and shortcomings of most manufacturer’s and suppliers we formed a team of professional engineers with a vast wealth of experience in CNC tube, wire and profile bending to develop three full ranges of new advanced, 21st century innovative production machines, along with the latest trend-setting and flexible software packages, that are loaded with benefits designed to help you maximise your production out-put to new increased levels. Combine all of the above with an interlinked machine refurbishment service and support programme, see below. This leading…

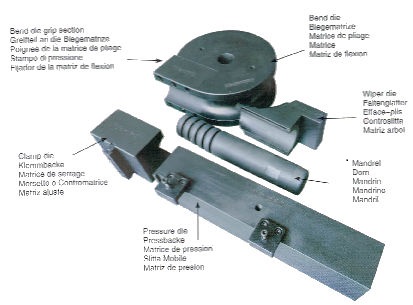

The Art of Mandrel Tube Bending The full Turn-Key package. If you are purchasing or have purchased a tube bending machine the following information will guide you on your way to manufacturing quality components. The main ingredients to manufacturing a superior quality component are. Tooling, Setting and a little splash of Lubricant. Tooling Bend-formers Sometimes referred to as a Bend Die. This is the main tool around which the tube bends. It has the shape of the tube machined around the periphery to contain it during the bending process. The radius from the centre of the former to the centre…

How to Bend TubeTo get the best wrinkle free results Have you ever tried to bend tube and every time it turns out creased and wrinkled? Bending a tube requires accuracy and precision. Every detail matters when making a smooth bend. Choosing the correct size bender, the correct tooling set, and the correct style of bender are all crucial factors. Download FREE PDF Buyers Guide Having the right size bending machine is the first thing to ensure you achieve an accurate and consistent quality bend. If the bender is too small, lacking power for the bending need, it will not hold…

Phenix is a 'unique' 21st century revolutionary, open source and expandable, efficient and economical intuitive system that unlocks and increases the power of digital on your old, out of warranty CNC & NC tube bending machine/s. So, when your budget doesn’t allow for a new machine, but your existing machines control and software is faulty, unreliable, virtually scrap. Your best low-cost solution is to... Keep and upgrade to 'Phenix' all of your existing CNC / NC tube bending machine/s. See for yourself, whether you’re completely new to CNC tube bending or a tenth-time returning customer our team of specialist tube…